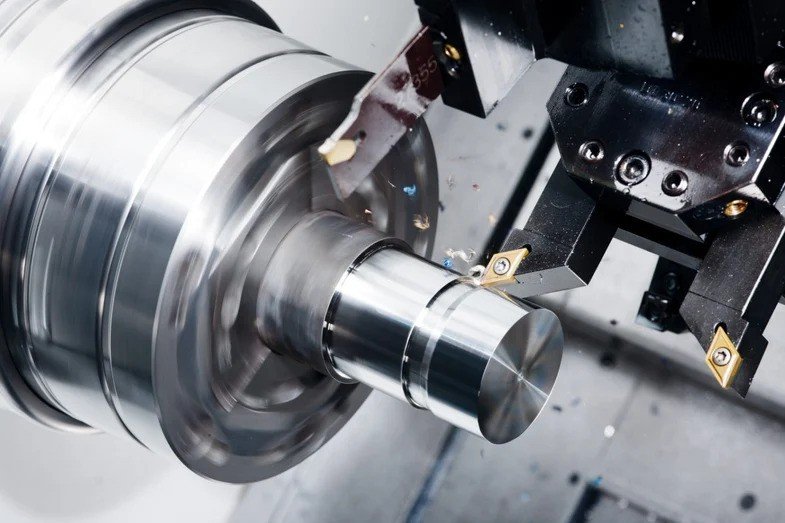

Facilities

At Imagineering Machine Inc., we pride ourselves on our state-of-the-art facilities equipped with advanced machinery and technology to meet the diverse needs of our customers. Our commitment to excellence extends to every aspect of our operations, ensuring precision, efficiency, and quality in every project we undertake.

CNC Milling

(2) Horizontal Machining Center

(3) Automated 5-Axis Machining Center with 60+ tools, 60 pallets, and Robotic Loading Cell

(11) 3-, 4-, and 5-Axis Machining Centers

Capacity up to 25” X 50” and up to 1000 lbs.

CNC Turning

(9) 3- and 4-Axis Turning Centers

Capacity up to 16” diameter and 200 lb. blanks

GRINDING

(2) Surface Grinder (<.0002)

(2) ID Hones (<.0002)

INSPECTION

Fully climate-controlled inspection lab with two Coordinate Measurement Machines (CMM), Keyence Optical inspection, Optical comparator, GagePack Calibration and Tooling Tracking software, and all records/processes per the ISO9001:2008 standard

GENERAL

Sand/bead blast, paint, and part marking.

Dedicated assembly area with a vast array of tools, curing oven, arbor press, and clean surfaces to ensure the highest quality before packaging.

Drive-up loading dock, forklift, and packaging/crating

Ready to Experience Precision and Excellence?

Ready to elevate your projects with unmatched precision and quality? At Imagineering Machine Inc., we're dedicated to delivering exceptional results. Whether you need precision machining, prototyping, or assembly services, our team is here to exceed your expectations.